Expertise

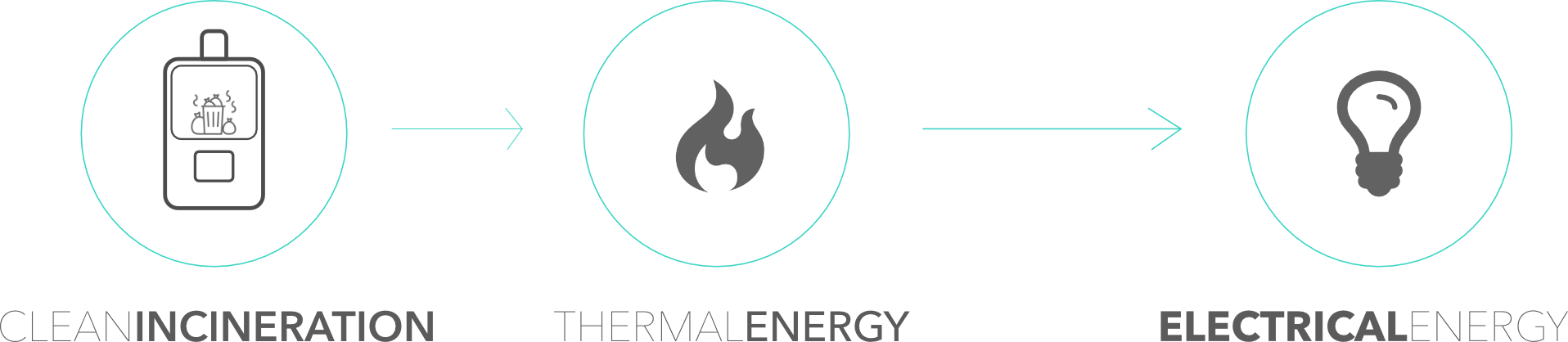

Methane Mitigation: Leading the Charge in Rapid Climate Action

The global warming potential (GWP) is a measure that compares the ability of a gas to retain heat

in the atmosphere in relation to carbon dioxide (CO2), whose GWP is equal to 1. The higher the

GWP of a gas, the more powerful it will be as a greenhouse gas.

Methane, with one carbon atom and four hydrogen atoms (CH4), has a GWP of 84 over a 20-year

period.

Thus, in terms of short-term global warming potential, methane is much more

harmful than carbon dioxide.

To combat climate change, reducing methane is crucial in

the short-term mitigation strategy."